Industrial Alarm Management

Achieve a faster response to machine breakdowns, quality incidents and maintenance calls with SIGNL4

How it works

What is industrial alarm management?

With SIGNL4, maintenance and operations teams become truly mobile and responses to potential issues become pretty much real-time. Machines or MES and SCADA systems can send urgent service or maintenance requests directly and automatically to mobile devices of on-call teams and responsible workforce. When on the shopfloor or at a large manufacturing facility, large distances need to be covered, yet speed is essential. SIGNL4 provides a fast, reliable, and mobile option to bridge such distances, reduce unnecessary alert noise and make industrial alarm management much more convenient.

“Thanks to SIGNL4, we have an automated, reliable and fast alerting process for our baggage handling system and other critical systems such as the docking guidance. This allows for guaranteeing a maximum response time of three min until remediation starts.”

How it works

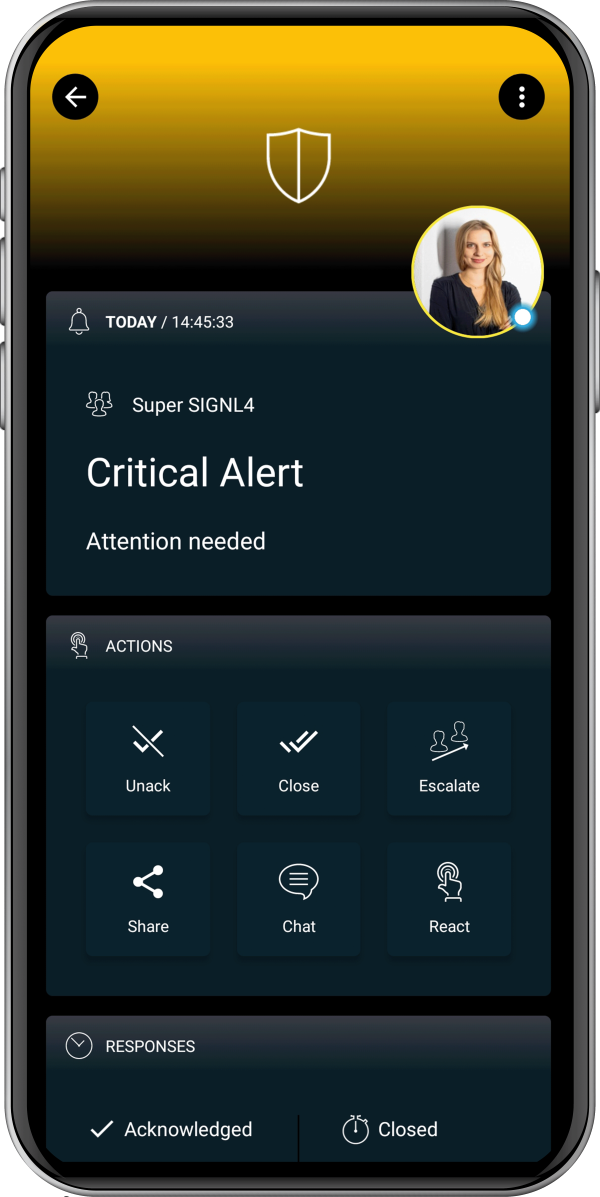

Notifications & Alarm Management

The mobile app of SIGNL4 displays an alert and job queue to workers on the plant floor. They can then take ownership of incidents, alerts, and service requests. In real-time, operators then see who responded or who took over which maintenance job. All is fully transparent and there is no need to search for idle team members or to ensure ownership has been taken. Later shifts can easily see what happened and which jobs were done or are still in the queue.

One-touch communication options help engineers to contact each other to solve problems jointly. An integrated chat allows for real-time communication between experts.

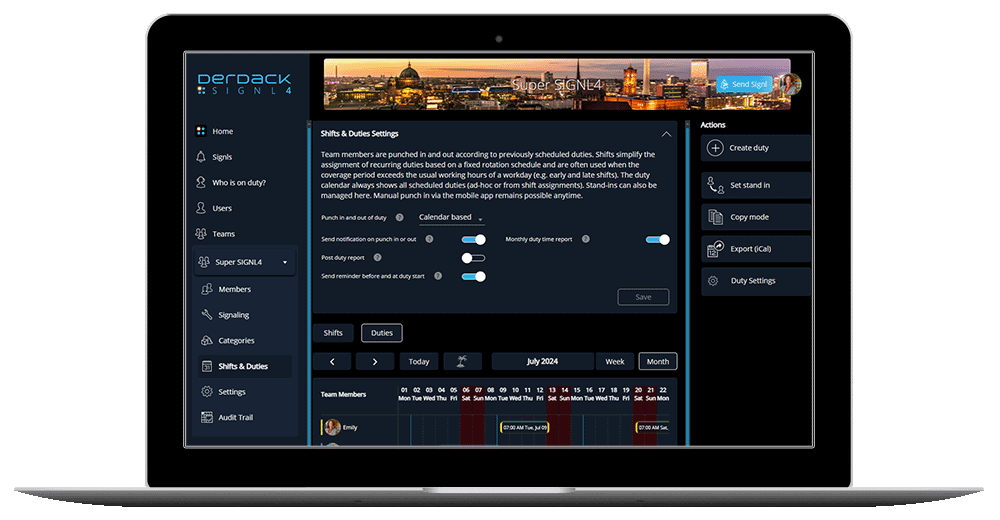

Duty and Shift Management

Integrated Duty Scheduling

SIGNL4 provides integrated, easy to use shift and duty scheduling. It provides for automated routing of critical alerts to staff on the shopfloor and to the right people at the right time. All you need is your browser to schedule your team’s availabilities.

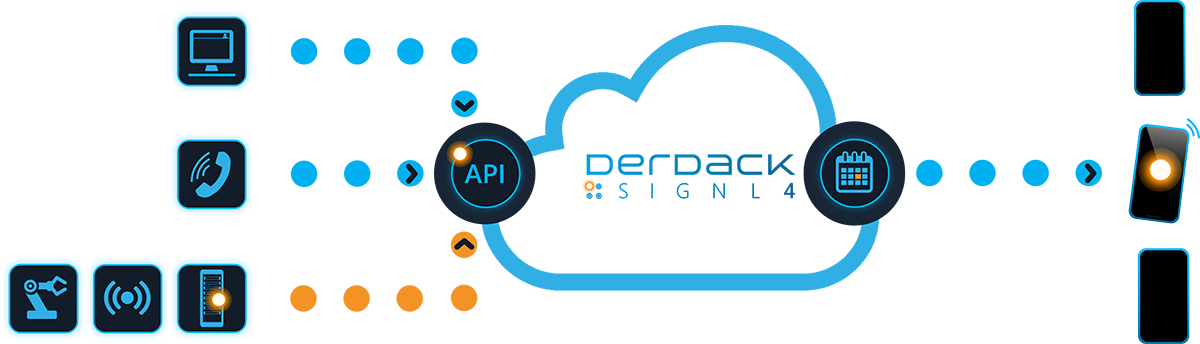

Seamless connectivity

Integrations and APIs

Integrates with SCADA and other manufacturing systems via Email, Webhook, REST and 2-way connectors. Optional S7 PLC connectivity with Edge Proxy. Consolidates events and alerts from multiple sources in IT, IoT, manufacturing, etc. 175+ tested and verified integrations.

Why SIGNL4?

Benefits

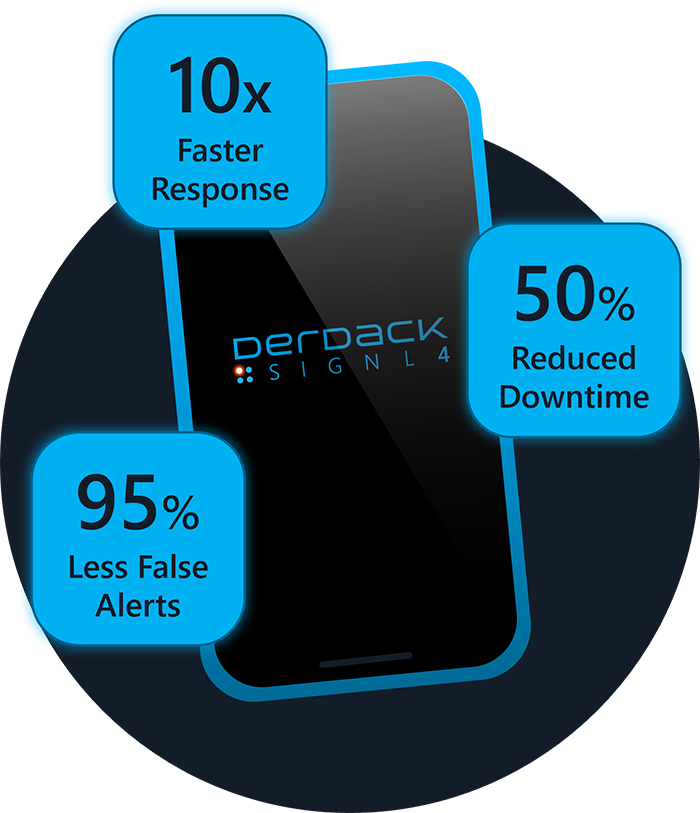

Automated mobile maintenance alerts and app-based industrial alarm management lead to a much faster response and handling of incidents, quality issues, service jobs or even interruption of manufacturing or machinery operations. Your Mean-Time-To-Response (MTTR) is reduced significantly. Alerts are targeted to your teams that are actively on duty and can respond to the issue at hand.

SIGNL4 offers an affordable, fast and easy option to enhance your operations. It is an essential building block of any smart and automated factory. The Return-On-Investment (ROI) is quick through the simplification and automation of previously manual processes.

A proven solution

Our customers

SIGNL4 has over 1,000 customers in Europe, North America and other regions. SIGNL4 rates 4-5 stars in app stores and on review sites like Capterra, GetApp and G2.

Next Steps

Learn more about SIGNL4 and start your free 30-days trial

Industrial Alarm Management Related Blogposts

May 2024 Update – New shift scheduling brings increased productivity and improved user experience, along with revamped stand-in functionality

Our May update includes a newly revamped shift scheduling for your SIGNL4 teams. It is now much easier to run your shift model in SIGNL4 and schedule team members into shifts. It also includes a new calendar view and a fundamental revision of our substitute function...

The Importance of Rapid Incident Response

An Incident Response Plan prepares an organization to deal with a security breach or cyber-attack. It defines the procedures an organization should follow if it discovers a possible cyber-attack, enabling it to detect, contain, and resolve problems promptly....

Enhancing Team Collaboration: Unveiling the Intuitive Features of SIGNL4

Effective communication lies at the heart of successful teamwork, and SIGNL4 emerges as a powerful tool crafted to elevate collaboration within teams. In this blog post, we will explore five of the often small but all the more intuitive features that distinguish...